Exploring advanced Aluminum Foundry techniques used in production

Uncovering the Conveniences and Practical Utilizes of Aluminum Castings in Today's Market

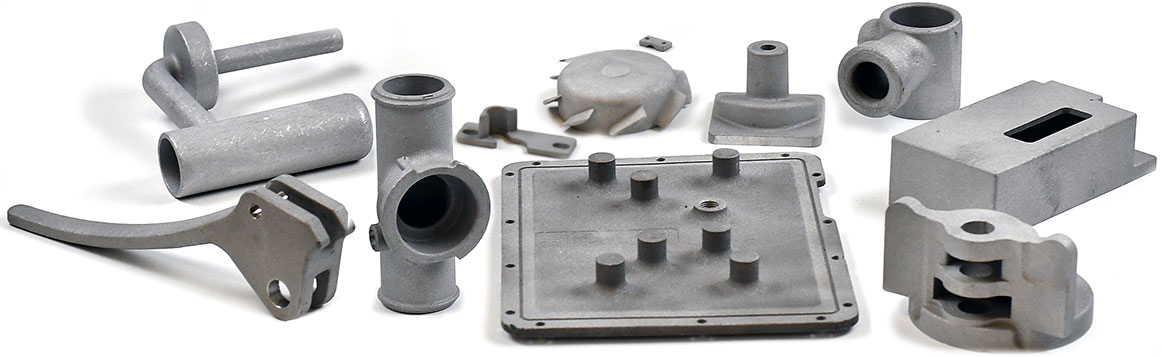

Aluminum spreadings have actually ended up being progressively relevant in different markets as a result of their special characteristics. Their light-weight nature and resistance to corrosion make them suitable for requiring applications. In addition, the superior strength-to-weight ratio supplies considerable benefits in style and manufacturing. As industries continue to explore their possibility, the complete scope of light weight aluminum castings' applications and benefits remains to be completely uncovered. What exists in advance for this versatile material?

The Lightweight Advantage of Light Weight Aluminum Castings

Many products are made use of in manufacturing, light weight aluminum spreadings stand out primarily due to their light-weight homes. This characteristic makes aluminum castings an eye-catching choice for numerous industries, especially in aerospace and auto applications, where weight reduction is vital for improving fuel efficiency and efficiency. The light-weight nature of light weight aluminum enables makers to develop parts that are easier to install and deal with, ultimately reducing labor costs.

The ability to produce intricate shapes without substantial weight fines makes it possible for designers to introduce while maintaining architectural stability. Aluminum spreadings can efficiently change much heavier products, bring about considerable financial savings in shipping and operational prices. Their light-weight advantage likewise adds to boosted product long life, as lighter components frequently bring about lowered deterioration on equipment. In general, the light-weight buildings of light weight aluminum castings supply makers with a competitive edge, fostering developments in product layout and effectiveness throughout numerous markets.

Exceptional Corrosion Resistance

Light weight aluminum castings possess a natural resistance to oxidation, which greatly boosts their long life in different atmospheres. This fundamental residential property not just adds to their sturdiness but additionally aligns with the light-weight benefit that light weight aluminum provides. As an outcome, light weight aluminum castings are significantly recognized for their phenomenal rust resistance in numerous applications.

Naturally Resistant to Oxidation

One of the standout characteristics of aluminum spreadings is their extraordinary rust resistance, which originates from an all-natural oxidation process. When subjected to air, aluminum responds to create a slim, protective layer of light weight aluminum oxide. This layer serves as a barrier against additional oxidation and shields the underlying steel from corrosive elements such as moisture and salts. Unlike other steels, this oxide layer is self-repairing; if damaged, it quickly reforms when revealed to air. This distinct residential or commercial property improves the long life of light weight aluminum spreadings in various environments, making them perfect for applications in markets such as aerospace, vehicle, and marine. As a result, the natural resistance to oxidation substantially minimizes upkeep expenses and boosts the integrity of aluminum castings sought after problems.

Light-weight Longevity Advantage

The light-weight nature of light weight aluminum castings adds substantially to their resilience, making them a helpful option in different markets. This remarkable sturdiness is mainly credited to aluminum's innate resistance to rust, which is improved even more via anodizing and other surface therapies. Unlike lots of metals, aluminum does not rust; rather, it forms a safety oxide layer that shields it from ecological damages. This property is particularly useful in industries such as auto and aerospace, where weight decrease is crucial without jeopardizing stamina. In addition, the longevity of light weight aluminum castings reduces upkeep prices and replacements, providing economic advantages gradually. Consequently, their light-weight durability and rust resistance position light weight aluminum castings as an exceptional material for contemporary manufacturing applications.

Superior Strength-to-Weight Proportion

A remarkable attribute of light weight aluminum castings is their remarkable strength-to-weight ratio, that makes them highly desirable in various applications. This intrinsic residential or commercial property enables aluminum castings to stand up to significant anxiety while staying light-weight, an essential consider industries such as aerospace, automotive, and manufacturing. Engineers typically favor aluminum castings for elements that need both durability and decreased weight, improving gas performance and efficiency.

The high strength-to-weight ratio also assists in the design of detailed forms and structures, making light weight aluminum spreadings flexible for complicated applications. The capability to keep architectural honesty under challenging conditions warranties durability and reliability in items, from aircraft structures to auto components. This benefit contributes to the growing pattern of utilizing light weight aluminum spreadings in innovative designs, inevitably causing improved functionality and performance across varied fields. The exceptional strength-to-weight proportion of aluminum castings positions them as a pivotal material in contemporary design and manufacturing.

Cost-Effectiveness in Production

Cost-effectiveness in light weight aluminum casting manufacturing is primarily accomplished through reduced product waste and efficient manufacturing processes. By maximizing designs and making use of innovative methods, producers can lessen excess material usage while preserving quality standards. This strategy not only reduces manufacturing prices however likewise contributes to extra sustainable methods within the industry.

Reduced Material Waste

Reducing product waste in aluminum casting processes significantly boosts manufacturing effectiveness. By enhancing the layout and manufacturing techniques, firms can decrease excess scrap and boost source use. This decrease in waste not only decreases product costs however likewise contributes to an extra sustainable production design. The ability to recycle light weight aluminum additional supports cost-effectiveness, permitting suppliers to redeem and recycle products without jeopardizing high quality. As the market increasingly concentrates on sustainability, minimized product More hints waste aligns with ecological goals while simultaneously enhancing productivity. Inevitably, effective use resources strengthens the affordable setting of businesses on the market, making aluminum spreadings a desirable option in numerous applications. The critical strategy to lessening he has a good point waste shows a commitment to both eco-friendly and economic responsibility.

Effective Production Processes

While standard production processes can incur substantial costs, light weight aluminum casting uses a much more efficient choice that improves overall manufacturing productivity. This approach lessens product waste and permits for exact control over the production process, causing decreased labor and functional prices. The capacity to produce intricate forms with fewer steps even more improves manufacturing, adding to much shorter lead times. Furthermore, aluminum's lightweight nature and excellent thermal conductivity enable energy cost savings throughout manufacturing and in the final application. By making use of contemporary casting technologies, manufacturers can attain higher throughput without compromising top quality. Aluminum casting stands out as an affordable option, making it an appealing option for services aiming to enhance their production processes in today's competitive market.

Convenience Across Industries

Light weight aluminum castings demonstrate remarkable adaptability throughout numerous sectors, as they can be customized to meet certain requirements and applications. In the vehicle sector, light weight aluminum spreadings are utilized in engine blocks, transmission housings, and wheels, supplying light-weight yet sturdy solutions that improve fuel effectiveness. The aerospace market additionally benefits from aluminum castings, using them in architectural elements and engine components as a result of their strength-to-weight proportion.

In the consumer items field, makers utilize light weight aluminum castings for products varying from cookware to furnishings, offering both aesthetic allure and capability. The electronic devices sector uses light weight aluminum castings for real estates and warm sinks, ensuring efficient thermal management. Additionally, the construction industry leverages aluminum castings for architectural aspects and structural elements, boosting longevity and layout adaptability. This broad applicability highlights light weight aluminum castings as a vital source, satisfying the varied needs of different markets while maintaining high efficiency and integrity.

Sustainability and Ecological Impact

As sectors significantly focus on sustainable techniques, light weight aluminum spreadings become an environmentally friendly choice because of their recyclability and reduced environmental footprint. Light weight aluminum is among the most recycled materials internationally, with the capability to be repurposed multiple times without degradation of quality. This characteristic significantly reduces the need for resources and energy usage connected with primary aluminum manufacturing, which is energy-intensive.

In addition, aluminum castings contribute to lightweight designs, leading to fuel effectiveness in transportation applications such as automotive and aerospace markets. Their longevity and resistance to corrosion extend item lifespans, further minimizing waste and source usage with time. Many producers are adopting liable sourcing and ecologically pleasant production approaches, enhancing the sustainability of aluminum casting processes. Overall, aluminum castings stand for a practical option for services intending to reduce their environmental impact while attaining performance and performance.

Innovations in Aluminum Spreading Technologies

Current developments in light check my site weight aluminum spreading innovations have actually considerably improved the performance and top quality of manufacturing processes. Advancements such as 3D printing and advanced mold-making techniques have actually enabled makers to develop complex layouts with decreased material waste. This change not only boosts the accuracy of cast parts yet additionally shortens lead times, permitting quick prototyping and faster market access.

The unification of innovative computer simulations help in predicting possible problems during casting, leading to higher-quality results. The usage of light-weight alloys has also added to the growth of stronger, extra sturdy items, accommodating sectors ranging from auto to aerospace

In addition, automated casting procedures have arised, lessening human error and increasing manufacturing speed. Collectively, these advancements are transforming the aluminum casting landscape, driving better competitiveness and sustainability in manufacturing. As sectors proceed to progress, these innovations will play an essential duty in conference future needs for performance and high quality.

Regularly Asked Questions

How Do Aluminum Castings Compare to Other Metals in Regards To Thermal Conductivity?

Light weight aluminum castings exhibit premium thermal conductivity compared to lots of metals, such as steel and iron - Wisconsin Aluminum Foundry. Their light-weight nature and reliable warmth distribution make them suitable for applications calling for effective thermal administration in numerous markets

What Are the Typical Flaws Found in Light Weight Aluminum Castings?

Typical issues in light weight aluminum spreadings consist of porosity, shrinkage, inclusions, and surface area abnormalities. These issues typically develop from inappropriate air conditioning rates, insufficient mold design, or contaminations, influencing the general high quality and efficiency of the last product.

Can Aluminum Castings Be Recycled, and Just how?

Aluminum spreadings can be reused successfully. The process includes collecting, melting, and changing the aluminum, which reduces waste and conserves sources. This reusing contributes to sustainability while keeping the material's properties for future use.

What Are the Typical Lead Times for Aluminum Spreading Production?

Typically, preparations for aluminum casting production range from 2 to six weeks, relying on elements such as complexity, tooling needs, and production volume. Performance can improve with well-known provider partnerships and maximized manufacturing processes.

How Does the Surface End Up Affect Light Weight Aluminum Spreading Efficiency?

The surface finish considerably impacts light weight aluminum casting efficiency by influencing corrosion resistance, visual quality, and rubbing qualities. A smoother surface enhances toughness and capability, while a rougher appearance can enhance adhesion for succeeding coverings or therapies.

Many products are made use of in production, light weight aluminum castings stand out largely due to their lightweight residential or commercial properties. When exposed to air, aluminum responds to create a thin, safety layer of aluminum oxide. Cost-effectiveness in aluminum spreading manufacturing is mostly accomplished via decreased material waste and reliable manufacturing processes. Reducing material waste in aluminum casting procedures substantially enhances manufacturing performance. Eventually, effective use of raw products strengthens the affordable setting of organizations in the market, making light weight aluminum spreadings a beneficial alternative in various applications.